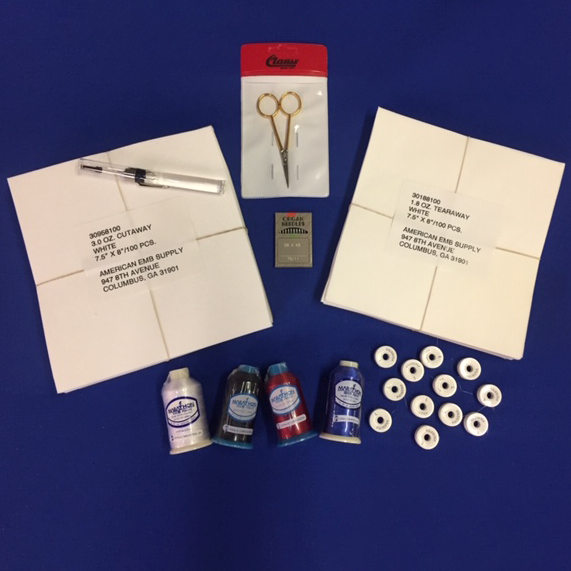

All About Stabilizers FAQ

Make sure your finished project looks its best by choosing the right stabilizer.

By Fred Lebow, consultant

Lebow Consulting

Q. What is a stabilizer?

A. A stabilizer is a piece of material that has been specifically designed to be used to provide support for embroidery. It is hooped along with the fabric or garment to be sewn. Stabilizer makes finished embroidery look better because the stitches are crisp and stable, and it also holds up better through the wash. With the proper stabilizer you minimize or eliminate problems such as loose stitches, puckering, and stitches that are out of registration.

Q. How are stabilizers made?

A. There are two methods for making stabilizers.

Dry-laid stabilizers include carded saturate or random, both of which work fine for interfacings—but neither of which is ideal for embroidery. This type is one directional.

Wet-laid stabilizers are made using a process similar to that used for the making fine paper. They are perfect for embroidery because they’re multidirectional, meaning they don’t stretch in any direction but can be torn in any direction. This manufacturing process also has a uniform, smooth surface, and if you choose the proper weight, you should need only one layer.

Q. How do I know which stabilizer to choose?

A. You should use one layer of stabilizer that’s the proper weight for your embroidery’s stitch count (number of stitches), stitch density (stitches per square inch), material, and material stretch. You want the stabilizer to be tight in the hoop approaching a “tambourine-skin” type tension so that the material doesn’t move, shift, or bounce.

Another consideration when choosing a stabilizer is to choose one that will be comfortable to wear and look nice. It should not be scratchy or bulky behind the embroidery. Even with stabilizer, fabric should drape nicely. (Who wants to wear a bulletproof vest?) Also, make sure you select a stabilizer that’s designed for the specific type of item you’re embroidering.

Q. What are the different types of stabilizer available?

A. Stabilizer types include cutaway, no-show cutaway, tearaway, hoopless adhesive, and water-soluble.

Cutaway

For home embroiderers, about 95% of the time, I strongly recommend cutaway backing. Cutaway stabilizer has longer fibers, which allows embroidery thread to tightly and

securely entangle itself within the backing material. This results in improved registration, and embroidery that holds up to more washings. I also recommend a cutaway with silicone. This makes it easier for the needle to enter and exit and allows scissors to “glide” across it when cutting.

Cutaway comes in three versions: lightweight, midweight, and heavyweight, ranging from 2 to 3 ounces. There’s no set formula on which stabilizer is best for a particular job. It’s important to test a variety of stabilizers in different weights with your embroidery piece. However, here are some general guidelines to give you a starting point:

• Lightweight for designs with 6,000 to 10,000 stitches, on knits and wovens.

• Midweight for designs with 10,000 to 18,000 stitches on heavyweight knits, fleece, and sweaters.

• Heavyweight for designs with 20,000 stitches or more, as well as heavyweight knits, fleece, sweaters, and home decorating projects (curtains, pillows, upholstery).

Although fabric plays a role in which weight you should use, ultimately, the most important determinant is stitch count and density. Your goal is to use a single layer of the lightest-weight stabilizer that will securely hold stitches. If your design starts having registration problems, try adding a second layer stabilizer. If that doesn’t solve the problem, move up to a heavier weight stabilizer. If you’re still having problems, the cause may be something other than the stabilizer, such as poor digitizing, tension issues, or the wrong size needle.

No-Show Diagonal Mesh Cutaway

A common problem with light-colored or sheer fabrics such as white piqué knits is the stabilizer is visible through the shirt. You can lessen or prevent show-through by using a lightweight, no-show diagonal cutaway. While other stabilizers are made from polyester or rayon, this soft-to-the-skin stabilizer is made from nylon for transparency and is embossed for maximum stability. It is available in white, black, and fusible.

Just one layer of no-show embossed mesh cutaway holds 10,000 to 12,000 stitches. If your design has more stitches, add a layer of tearaway.

No-show stabilizer comes in nonfusible or fusible versions, the latter of which eliminates the need for adhesive sprays. You apply it by ironing the fusible stabilizer onto the fabric using a low temperature iron (250 to 260 degrees).

Adhesive sprays can cause a range of problems such as gumming up the needles and other parts of the machine and contaminating the air. Fusible stabilizer allows you to get the extra stability you need without the use of messy sprays.

Tearaway

Tearaway stabilizers have shorter fibers so they do not provide as secure a hold on embroidery stitches as cutaway. However, some people prefer them because the excess is simply ripped away. It does not require the more time-consuming step of

trimming with scissors. It comes in weights from one to three ounces and is most appropriate for stable fabrics such as heavy jean material, canvas, cotton twills, work jackets, towels, and robes. Although you may not think these heavy fabrics need stabilizer, tearaway backing provides tighter, sharper registration, especially with high stitch counts.

Fusible tearaway backing is available in a medium weight (1.5 ounces) for linens, tablecloths, and napkins where adhesive sprays are not desirable.

Hoopless Adhesive

For hard-to-hoop items like baby booties and tote bags and impressionable fabrics such as velvets and silks where hoop burn could be a problem, a moisture-activated, adhesive-backed stabilizer is a great solution. It eliminates potential problems with spray adhesives as noted above and peel-and-stick backings, which also can gum up your needles.

It’s easy to use: Just cut a piece of adhesive-backed stabilizer larger than the hoop and hoop it adhesive side up. Activate the adhesive with a small amount of water and position the item onto the tacky surface. Some brands include a handy grid that makes alignment and positioning easier.

Adhesive-backed stabilizer comes in cutaway and tearaway versions. Embroiderers generally choose the cutaway version for less stable items and when backing show-through is not a problem. Tearaway is preferred for items where the back will be visible.

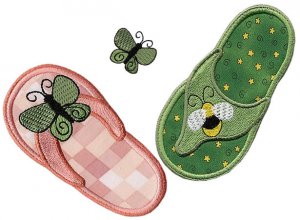

Water-Solubles

Water-Soluble For Lace. For items such as lace, freestanding appliqués, and emblems, where you don’t want any leftover stabilizer, water-soluble is a great solution. Unlike films, which can fall away leaving nothing to hold stitches in place, water-soluble stabilizer is made from fibers so that embroidery thread entangles itself and provides needed stability. After you’re finished stitching the piece, the stabilizer completely dissolves in warm water.

Water-Soluble Tearaway. This paper-like stabilizer is made up of soluble and nonsoluble fibers and is ideal for decorative stitching; heirloom pieces; or open, light embroidery where the back of the design is visible. Because it washes out, there are no shadows left behind design nor will you spend long hours picking out stabilizer. It’s also designed to do paper piecing for quilts. You can actually run it through your computer printer and print quilt patterns on it. These can be cut out and pinned to the appropriate fabric.

Water-Soluble Topping. Toppings do not offer stability; instead, they provide a smooth embroidery surface for high-piled fabrics such as corduroy, terrycloth, and fleece. Water-soluble toppings, usually made from PVA film, keep stitches from sinking into the fabric and provide crisp definition. Just cut a piece of topping to fit your hoop and either place it on the hooped fabric, or hoop it with the fabric. After stitching, tear away as much of the topping as possible and dissolve any remaining pieces with water or a

steamer.

Cotswold Press and Tear

Got something that won’t fit in a hoop like a sock or a necktie? Use a hoopless embroidery stabilizer. This specialized stabilizer either has a water-activated adhesive.

Cotswold Washaway

When you don’t want an embroidery stabilizer to show, use a water soluble. Once you are finished sewing, excess can be removed by using a steamer or soaking it in warm water.

AES Diagonal No Show Mesh

Diagonal No Show Mesh is specifically designed to be used with light-colored fabrics where traditional stabilizer shows through the front of the shirt. It is made of nylon mesh with a diagonal embossed pattern, which makes it more directionally stable. This allows it to hold more stitches per single layer than traditional perpendicular patterned mesh.

Cotswold Cutaway

The first choice for most embroidery projects should be a cutaway. This type of stabilizer provides the best stability and tightest registration.

Cotswold Tearaway

A tearaway stabilizer does not provide as much stability as a cutaway, but it speeds up production time because it can be torn away instead of trimming it with scissors.